AutoStore

This specialist article describes what is behind the automated warehouse system, how it revolutionizes intralogistics and the advantages it provides.

Product Managerin

What is AutoStore?

AutoStore is an innovative and automated warehouse system from Norway, which revolutionizes intralogistics worldwide by combining high storage density with efficient picking. Due to its form and density, it is frequently described as “cube storage” warehouse.

The fastest “goods to person” solution enables enterprises to maximize their storage capacities and accelerate order processing. AutoStore has established itself as a leading technology for automated storage and picking of small parts.

As an alternative to a small parts storage area and in contrast to conventional shelf storage areas, AutoStore does not require any additional space and not necessarily much space between the individual articles either due to its structure.

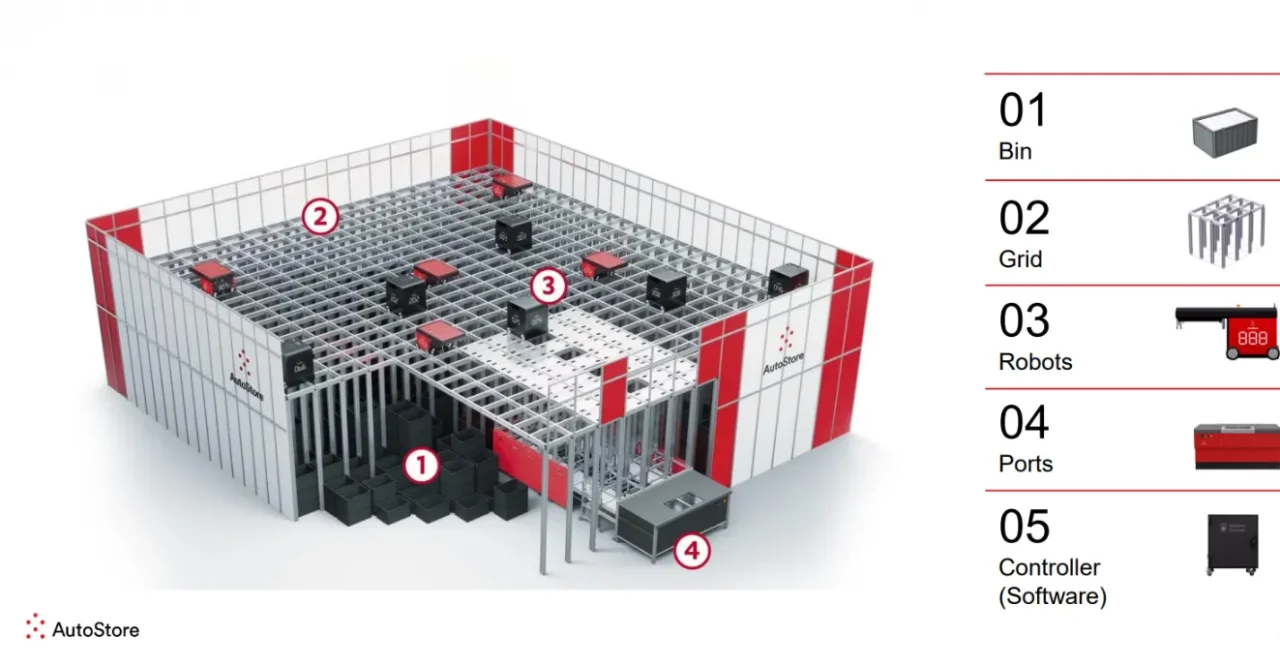

How is an AutoStore system structured and how does it work?

Conventional systems for warehouse automation require space for walkways and driveways through the storage area. An AutoStore system, however, uses a grid structure, whereby this space is saved within the warehouse and the complete available space is utilized in the entire storage height.

The system consists of only five modules: The articles are stored in “bins” that are stacked next to each other as well as on top of each other in an aluminum grid. This stacking principle is similar to that of building blocks. On the grid, robots continuously move on tracks, “dig out” the bins, withdraw them from the grid and take them to “ports” (workstations). The “key pillars” of this procedure are speed, accuracy and efficiency.

The AutoStore robots move on the upper side of the grid at a speed of up to four meters per second and, in doing so, automatically put away the containers and remove them from stock.

Picking takes place at the work centers, which are connected to the existing intralogistics. The controller is the interface for the internal data flow and provides fast access to stock data in cooperation with any warehouse management software.

What are the benefits of an AutoStore system?

In addition to flexibility, efficiency and scalability, the automatic storage and picking system provides numerous benefits for enterprises. For planning and implementing an AutoStore system, however, the specific requirements and conditions in the warehouse of the respective user must be taken into account to ensure an optimal solution.

Where can AutoStore be used?

An AutoStore system is particularly suitable for the following application areas and industry sectors:

How do automated storage techniques and SAP EWM harmonize perfectly?

Example of an AutoStore implementation

An advanced logistics hardware application such as AutoStore requires an equally advanced software integration. In addition to AutoStore hardware and an advanced SAP Extended Warehouse Management (EWM) system, an agile, intelligent and highly integrated SAP connection is needed as otherwise AutoStore cannot unfold its added value.

A cosmetics manufacturer has targeted a digitization of its entire storage techniques for automatic and robot-supported storage and picking of small parts. First of all, the existing SAP Extended Warehouse Management system was individualized by adjusting it to its corporate processes. Moreover, an intelligent and highly integrated SAP connection of the AutoStore hardware was implemented into the advanced SAP EWM system. By implementing SAP EWM and the downstream AutoStore connection, it was possible to successfully harmonize the entire storage techniques including SAP connection in such a way that logistical processes could be optimized.

Conclusion

The AutoStore system is an innovative and highly efficient solution for automated storage and picking of small parts. Due to its space-saving construction, high storage density and fast goods movement, it revolutionizes intralogistics and enables flexible scaling in accordance with operational requirements. The seamless integration with SAP EWM ensures optimal control and synchronization of the processes, which significantly increases efficiency and transparency in warehouse management.

AutoStore is particularly suitable for industry sectors with high small parts occurrence such as e-commerce, food, electronics or pharmaceutical industry and can be integrated into various building structures. Thanks to its high availability, energy efficiency and extensibility, it is a future-proof investment, which maximizes storage capacities and reduces personnel costs.

As a whole, AutoStore is a future-oriented solution that raises warehouse logistics to the next level and supports enterprises in optimizing their processes and becoming more competitive.