SAP Extended Warehouse Management (SAP EWM)

This specialist article describes how you can use SAP Extended Warehouse Management to make your warehouse management efficient and consistently optimize your supply chain.

Product Managerin

- What is SAP Extended Warehouse Management?

- What are the current challenges in the area of warehouse management?

- What advantages and benefits are provided by SAP EWM?

- How does it function and what does the FIS/ewm+ implementation template mean?

- What kind of enterprise is SAP EWM suitable for?

- Individual processes without system risks: flexibility in the standard version – how does this work?

- What does the SAP EWM scope of services include?

- Are there mobile logistics devices and apps and how are these connected?

- How can SAP EWM and SAP TM be seamlessly integrated in the order processing process using Advanced Shipping & Receiving?

- Conclusion

- FAQ – Frequently asked questions

What is SAP Extended Warehouse Management?

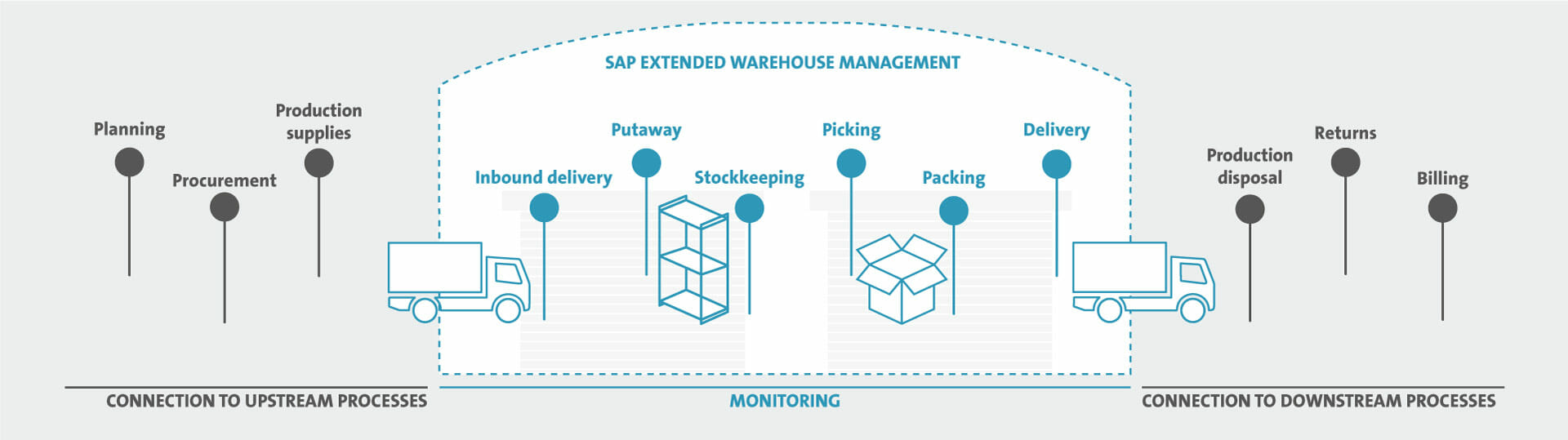

SAP Extended Warehouse Management (SAP EWM) is a highly standardized and high-performance Warehouse Management system that flexibly supports all logistics processes for warehouse controlling from goods receipt and stockholding to picking and shipping.

Just like SAP Transportation Management (SAP TM), the Warehouse Management system belongs to SAP Supply Chain Execution Platform (SAP SCE) and is part of SAP Supply Chain Management (SAP SCM). Together, these solutions fulfill the requirements of modern logistics from simple and manual to highly complex warehouses. SAP EWM is a particularly flexible system meeting the demands of different warehouse types.

The system combines comprehensive functions and the increased efficiency of logistics processes in the warehouse. SAP EWM is fully integrated into inventory management and delivery processing. It can also be used for organizing, controlling and monitoring stock movements and, at the same time, it offers a system for controlling key figures. SAP EWM enables the highest possible transparency and control of warehouse processes by controlling the processes of big in-warehouse quantities and integrating complex supply chain logistics into the warehouse and sales processes of logistics companies.

SAP EWM enables the optimization and automation of warehouse logistics processes and, consequently, ensures faster and more efficient process flows.

What are the current challenges in the area of warehouse management?

Far-reaching potentials with regard to optimizations, cost savings in the warehouse and increased customer satisfaction are underestimated by numerous companies. In some cases, warehouse structures have grown over the years, various IT solutions have been purchased and combined, which makes IT infrastructures more and more complex. In other cases, the Warehouse Management system used is obsolete and rigid and has therefore become nontransparent and cost-intensive in the long run. In addition, there are current problems such as permanent skills shortage and inefficiencies in the management of warehouse processes.

Time-intensive activities, such as manual picking via picklist, can be reduced or even eliminated through paperless and automated warehouse management. As a consequence, errors are avoided.

Putaways of goods and stock removals are controlled and monitored through digitization. This enables efficient supply chain management and companies can respond more quickly to customer demands and requirements.

The strategic Warehouse Management system enables the timely provision of goods at the right place. In this way, production downtimes or even interruptions are avoided and goods deliveries, in particular e-commerce deliveries, are accelerated. The advantages of SAP EWM are reflected in a functioning warehouse and inventory management and, therefore, offer big economic chances for companies.

What advantages and benefits are provided by SAP EWM?

FIS complements these benefits by its FIS/ewm+ project turbo. This methodology specifically provided for the SAP EWM implementation enables a particularly convenient and rapid implementation of the Extended Warehouse Management software, which complements the SAP standard version.

How does it function and what does the FIS/ewm+ implementation template mean?

The high flexibility of SAP Extended Warehouse Management (EWM) requires a detailed and precise process design that is used as a basis for Customizing and, if necessary, development activities.

The FIS/ewm+ project implementation template includes predefined documented processes and therefore accelerates the SAP EWM implementation. The necessary Customizing is preconfigured as well, which simplifies the step towards implementation.

All template processes are configured as consistent end-to-end processes. They are seamlessly integrated into SAP ERP as well as adjacent logistics areas. In addition to the EWM standard version, FIS/ewm+ provides optimized radio dialogs for paperless warehouse processes as well as a multitude of improved dialogs and predefined print forms.

This simplifies operability and enables mobile data entry. Training courses at an early stage help users quickly become familiar with the EWM system, which further shortens the explore phase. The quick implementation considerably reduces the costs for the implementation of SAP EWM.

Benefit resulting from the FIS/ewm+ implementation template

What kind of enterprise is SAP EWM suitable for?

SAP EWM is suitable for enterprises whose warehouse and logistics processes are very complex and who are looking for an efficient, transparent and flexible solution. This concerns, for instance,

What does the SAP EWM scope of services include?

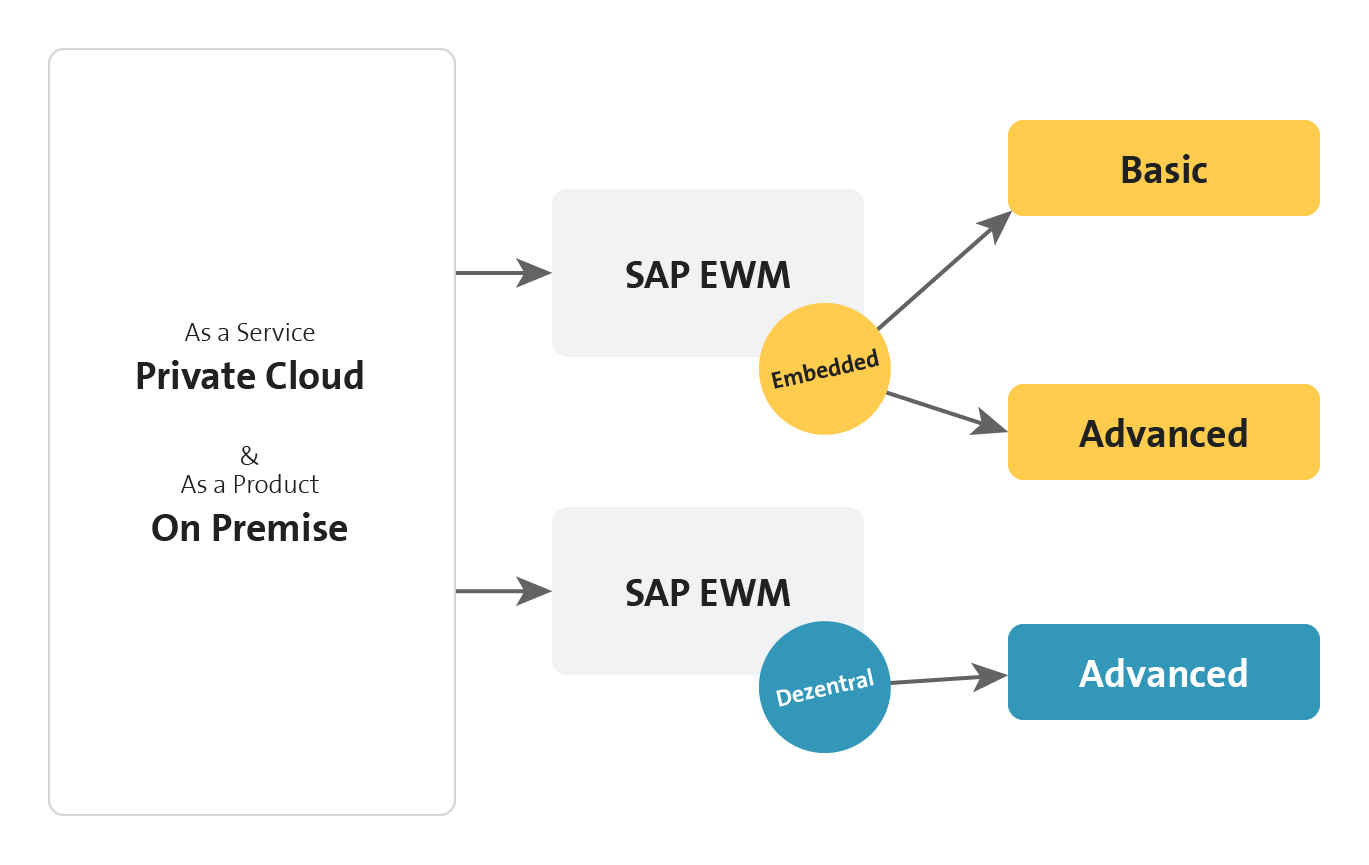

SAP Extended Warehouse Management (EWM) is based on S/4HANA, the advanced SAP ERP system including the HANA real-time database. This ensures a standardized data basis for all those involved. As a consequence, reliable decisions in the supply chain management environment can be made in good time.

SAP Extended Warehouse Management focuses on the system mapping of the following warehouse logistics core processes:

SAP EWM fulfils the highest requirements of warehouse automation with regard to functional scope and controllable complexity. The Warehouse Management system enables, for instance, the implementation of complex conveyor systems, stacker control systems or automatic small parts storage areas (SPSA). Simple warehouse structures can also be mapped without any problems using SAP Extended Warehouse Management.

Detailed listing of the SAP EWM functional scope

Goods receipt

Production supply and production disposal

Stockholding & inventory management

Goods Issue

Are there mobile logistics devices and apps and how are these connected?

Skilled warehouse workers rely on the use of mobile devices in order to work more efficiently and ergonomically. This includes smartphones and tablets, bar code scanners and other GPS technologies. A Warehouse Management system (WMS) that can support the connection of these technologies is of crucial importance.

Mobile SAP-based logistics apps offer digital support in the field of intralogistics and transport and ensure the highest possible overview of all logistics processes.

The harmonization of business processes, an efficient use of existing resources as well as the optimization of goods movements are the greatest advantages of supply chain digitization and upstream/downstream processes.

Mobile apps are seamlessly integrated into the SAP system. They are field-tested extensions complementing the SAP standard version by useful functions. The sustainable applications can be used on mobile devices and therefore create consistent logistics processes. The intuitive and user-friendly operation enables the employees to work ergonomically and efficiently. With an appropriate Internet connection, all information is available in real time without interface losses.

How can SAP EWM and SAP TM be seamlessly integrated in the order processing process using Advanced Shipping & Receiving?

Today, the smooth processing of sales orders and the seamless integration of warehouse management and transportation planning requires more than just system support. Instead, SAP EWM and SAP TM have to work synchronously in order to ensure swift order processing from a logistics point of view.

Conclusion

SAP Extended Warehouse Management (SAP EWM) is a high-performance solution for advanced warehouse management. It supports companies in optimizing their logistics processes and increasing supply chain efficiency. In light of the current challenges of warehouse management, such as complex IT infrastructures and skills shortage, SAP EWM offers a flexible and scalable platform that can be adjusted to the individual requirements of different companies.

The advantages of SAP EWM, i.e. real-time transparency, optimized space utilization and seamless integration into existing systems, help reduce costs and increase customer satisfaction. In addition, the FIS/ewm+ implementation template considerably accelerates the implementation process, which improves user acceptance and reduces the total of implementation costs.

Altogether, SAP EWM is particularly suitable for companies with complex warehouse and logistics processes that are looking for an efficient and transparent solution in order to increase their competitiveness and quickly respond to the dynamic requirements of the market.