Unloading pallets, supplying building materials and documenting documents, notes and signatures for goods deliveries: with pen and paper in the past, today via smartphone or tablet. During its one-year pilot phase with the Raab Karcher, Muffenrohr and Melle Gallhöfer sales brands, STARK Deutschland was convinced by the advantages of the SAP-based FIS/LastMile goods delivery app so that it is now rolled out to the entire company. The digital and paperless documentation of goods deliveries ensures faster work processes with much more efficiency and makes “the last mile” fully transparent.

Home | News & Downloads |

Successful start into 2025: In April, on the occasion of the first customer satisfaction survey of the year, the FIS customers rated 393 service tickets on the basis of FIS/oss ticket processing. The result: 384 tickets received the highest rating of 4 stars, which corresponds to a share of 97.7 % of most satisfied customers. With additional consideration of the tickets with a 3 stars rating, i.e. a “good” rating, the overall satisfaction achieves the outstanding result of 99 %.

Newly concluded partnership underlines commitment for a future-oriented, innovative and scalable transformation towards SAP S/4HANA Cloud Public Edition.

Manual efforts for the transmission of orders, little process automation or none at all, missing monitoring and complex in-house development for necessary interfaces - all that should no longer be relevant for shop connections. FIS/ShopConnector offers a universal connection of existing Web shops to SAP S/4HANA: quickly, easily and safely.

At this year's LogiMAT logistics trade show (March 11 - 13, 2025), FIS Informationssysteme und Consulting GmbH, which is specialized in SAP solutions, will be presenting self-developed optimizations and templates to enhance SAP standard. The portfolio is complemented by mobile apps for consistent logistics processes and SAP solutions for warehouse management and transport logistics. FIS will be exhibiting at stand A31 in hall 4.

Grafenrheinfeld, Tuesday, 7. January 2025 – FIS Informationssysteme und Consulting GmbH, an SAP partner with "Gold" status, and Centric IT Solutions GmbH, an SAP "Focus Partner", have already cooperated with each other in projects and at joint events. Now, they have formalized their cooperation with a partner agreement in order to optimize digital Personnel- and Payroll Processes in SAP.

FIS Informationssysteme und Consulting GmbH was once again able to pass the check of almost 2,600 test points for SAP Extended Warehouse Management. This is confirmed by this year's validation by the Fraunhofer Institute for Material Flow and Logistics (IML) and the listing on warehouse-logistics, the leading portal for warehouse management systems (WMS). The special expertise of FIS lies in EWM implementation and connection to ERP core processes.

Today, FIS Informationssysteme und Consulting GmbH announced that its FIS/TradeFlex solution was once more certified by SAP for SAP Business Technology Platform (SAP BTP). This software solution assists SAP users in optimizing their sales on online marketplaces by automating all relevant processes.

FIS Informationssysteme und Consulting GmbH continues its strategic further development and strengthens its executive board with a new department: "Business Transformation and SAP Cloud". As of October 1st, 2024, Michael Benirschka, a qualified expert in the area of the current SAP solution strategy and long-time SAP manager, assumes responsibility for this business area.

Once again, FIT/One Würzburg Baskets may welcome a new top sponsor from this region: FIS Informationssysteme und Consulting GmbH, founded in 1992 and based in Grafenrheinfeld/Lower Franconia, is firmly rooted in this region and, at the same time, operates globally. The company intends to use the new partnership, which, for a start, was agreed upon for one year, for instance to attract skilled labor.

On Friday, July 19, 2023, the second Vocational Training Day took place at the FIS Group. With high summer temperatures, the event attracted around 200 visitors with a varied program dedicated to vocational training and dual study program.

As a regular supporter of MainCityRun organized by TG48 Schweinfurt Laufen-Triathlon, FIS Informationssysteme und Consulting GmbH invited to a donation delivery in Grafenrheinfeld.

When reviewing the MCR event, FIS decided to generously round up the donation amount collected by its staff during the run to EUR 500.00, which was handed over to representatives of Franziskus-Schule Schweinfurt at the FIS headquarters in Grafenrheinfeld on August 01, 2024. Prior to the MCR, FIS motivated its employees by the "We will donate 1 Euro for each kilometer run" action.

FIS offers trendsetting expert knowledge on the path to digitization as well as unique networking to more than 200 participants.

At this year's SAP Diamond Initiative, FIS Informationssysteme und Consulting GmbH was recognized as a Focus Partner in the field of "Retail & Consumer Products". This once more confirms the SAP expertise of FIS.

For the seventh time in a row, FIS Informationssysteme und Consulting GmbH, an SAP partner with "Gold" status, was certified as SAP Partner Center of Expertise (PCoE).

The FIS Group sets an impressive sign for environmental protection and sustainability by planting a forest with 800 trees in Pegnitz (Upper Franconia). The number of the planted trees stands for the 800 employees of the FIS Group consisting of the three enterprises FIS Informationssysteme und Consulting GmbH (FIS), FIS-ASP Application Service Providing und IT-Outsourcing GmbH (ASP) and Medienwerft – Agentur für digitale Medien und Kommunikation GmbH (Medienwerft).

FIS Informationssysteme und Consulting GmbH today announced that its FIS/edc solution for sales orders is available on SAP Store. The application creates optimized sales processes and minimizes the current efforts by means of automated order processing.

FIS Informationssysteme und Consulting GmbH has obtained the SAP Business Technology Platform (SAP BTP) "Expert" status. It shows companies how to find the right consulting and implementation partner for their business challenges in the cloud.

FIS Informationssysteme und Consulting GmbH and BPM&O GmbH are announcing their strategic partnership. BPM&O is a consulting company focusing on process management and process-oriented organization development. This means that BPM&O perfectly complements the competence of FIS, an SAP partner with "Gold" status, when it comes to SAP consulting and executing SAP projects.

Today, FIS Informationssysteme und Consulting GmbH announced that its FIS/TradeFlex solution was once more certified by SAP for SAP Business Technology Platform (SAP BTP). The application makes it easier for SAP users to sell their products on online marketplaces through the automation of all relevant processes.

For FIS Informationssysteme und Consulting GmbH (FIS), the recruitment and retention of valuable skilled labor also forms an important cornerstone of future success. Therefore, the management board reorients itself as of January 1st, 2024. With Eva Baumeister, an experienced FIS executive will join the management board.

FIS Informationssysteme und Consulting GmbH (FIS) does without Christmas presents for customers and partners and instead donates 15,000 Euros to UNICEF.

Companies are often looking for an integrated application to optimize their master data management in the course of ongoing digitization and the transition to SAP S/4HANA. Werner & Mertz, a manufacturer of cleaning products, care products and detergents, also wanted to improve and simplify its material creation processes.

FIS Informationssysteme und Consulting GmbH (FIS) from Grafenrheinfeld is the 53rd main sponsor of the “Wildpark an den Eichen” (“Wildlife Park at the Oaks”) in Schweinfurt and was honored with the “Beo” Cross of Merit on October 17, 2023.

After four successfully completed training rounds, FIS Informationssysteme und Consulting GmbH (FIS) is looking forward to already entering its fifth round of the annual trainee program. In 2023, as in the past few years, a group of graduates will again be trained as certified SAP consultants in the course of this program.

With the FIS Warehouse Check, our experts will show you how you can take your intralogistics to a new level through targeted optimization of your logistics processes and SAP systems.

In bright sunshine, FIS inaugurated the new office building at its headquarters in Grafenrheinfeld on Tuesday, September 5, together with Florian Töpper, district administrator, Christian Keller, first mayor of the municipality of Grafenrheinfeld, and Thomas Weiss, deacon of the “Zu den Frankenaposteln im Maintal” (“To the Apostles of Franconia in the Main Valley”) parish community.

At the beginning of September, nine new trainees started their vocational training at FIS Informationssysteme und Consulting GmbH (FIS): eight trainees (m/f/d) as IT specialists for application development and one female trainee as office management assistant. This year's particularity: right from the beginning, all trainees start at the new FIS Academy, the newly built vocational training center of FIS. It is a pleasure for FIS that state-of-the-art work centers, co-working rooms and creative spaces are being used by the new trainees.

On Friday, July 21, 2023, the first vocational training day took place at the FIS Group. The event attracted around 300 visitors with a varied program dedicated to vocational trainings and dual study programs.

This year, FIS Informationssysteme und Consulting GmbH (FIS) has received the BAYERNS BEST 50 (BAVARIA'S BEST 50) award for the third time. This renowned award is in recognition of the 50 most successful small and medium-sized companies in Bavaria and honors their outstanding entrepreneurial performance and sustainable growth.

In the foreseeable future, SAP will discontinue the maintenance for its Process Integration (PI) and Process Orchestration (PO). Therefore, it is now time to migrate to a succession solution, such as SAP Integration Suite. FIS Informationssysteme und Consulting GmbH provides companies with the corresponding support and even offers a separate tool for business process integration alternatively or in addition to the SAP solution: FIS/xee.

Since May 2023, FIS Informationssysteme und Consulting GmbH (FIS) has been an official supporter of "Allianz für Entwicklung und Klima" (= "Alliance for Development and Climate").

Since 2017, the Allgemeine Deutsche Fahrrad-Club (ADFC; General German Cycling Club) has awarded the EU-wide "Bike-Friendly Employer" certification. Now, FIS headquartered in Grafenrheinfeld has received the coveted "silver" certificate.

The HR transformation is in full swing and the SAP universe is focused on issues such as SAP HCM for S/4HANA (H4S4), preparations for the cloud and the question of how SAP HCM users prepare themselves for the future. On May 11, 2023, the first shared HR day of FIS and Centric Germany took place and was very well received by more than 80 participants.

FIS Informationssysteme und Consulting GmbH arouses the interest of pupils for the MINT area by organizing a workshop on "Conception and Programming".

“Once you have eaten and drunk, you feel like newly born; you are stronger, braver, more skilled in your negotiations.”

As this quote by Johann Wolfgang von Goethe is credited by Grafenrheinfeld companies “FIS Informationssysteme und Consulting GmbH” (“FIS”), “FIS-ASP Application Service Providing und IT-Outsourcing GmbH” (“FIS-ASP”) and “TRIPS GmbH”, they follow new paths with “BIG oHG” in their jointly operated staff restaurant.

By integrating with SAP Business Technology Platform, FIS/bxp Open Document Exchange solution from FIS Informationssysteme und Consulting GmbH delivers a central platform for efficient and standardized digital data and document exchange in wholesale trade to customers.

Intelligent material requirements planning and goods distribution for the location in Hungary. FIS Informationssysteme und Consulting GmbH has established an individual SAP plant for the RAFI Group in Hungary. With the intelligent FIS logic, the goods can be planned in a time-, quantity- and requirement-oriented way. This enables process standardization as well as optimal stock and requirement transparency.

FIS Informationssysteme und Consulting GmbH and Medienwerft - Agentur für digitale Medien und Kommunikation GmbH jointly received the SAP CX Expert status at the beginning of the year. It shows companies how to find the right consulting and implementation partner for their business challenges in the cloud.

FIS Informationssysteme und Consulting GmbH has received the “Retail & Consumer Products - Partner of the Year 2023” award at this year’s SAP Diamond Initiative. This makes FIS an SAP focus partner and demonstrates its own expertise in all aspects of SAP solutions.

FIS Informationssysteme und Consulting GmbH has successfully implemented SAP Marketing Cloud at Swiss enterprise Walter Meier (Fertigungslösungen) AG. With this solution, the machinery importer now automates diverse marketing processes and significantly reduces administrative efforts.

On January 7, FIS Informationssysteme und Consulting GmbH (FIS) welcomed four new dual system students to their first practical phase at the company’s headquarters in Grafenrheinfeld.

Grafenrheinfeld, December 22, 2022. Gaining customers is hard enough - retaining them is even harder. This year again, the FIS Customer Expert Service team managed to completely satisfy its customers and score points with excellent service. This is confirmed by the top ratings achieved in the biannual customer satisfaction survey.

This year again, FIS Informationssystem und Consulting GmbH (FIS) continues its tradition and dipenses with Christmas gifts for its customers. Instead, the IT enterprise from Grafenrheinfeld donated 15,000 Euro to “Kindernothilfe e.V.” (“Kindernothilfe” a registered charity organization founded to help children in need) to support Ukrainian refugee families.

Since 2022, FIS Informationssysteme und Consulting GmbH (FIS) has been a proud sponsor of Wissenswerkstatt Schweinfurt e.V. (Knowledge Workshop Schweinfurt). In addition to financial support, FIS also participates in the implementation of events on the subject of 'coding'. The certificates were officially awarded on October 26, 2022.

After three successful years, the fourth one is starting now: This year again, FIS Informationssysteme und Consulting GmbH (FIS) will train university graduates as certified SAP consultants in the course of its trainee program.

On September 01, 2022, FIS welcomed a total of 12 new trainees and dual system students at the company’s headquarters in Grafenrheinfeld.

Leukemia can affect anyone. However, leukemia is curable if a suitable donor can be found in time.

Under this motto, 650 employees, partners and special guests of FIS Informationssysteme und Consulting GmbH (FIS) celebrated last Saturday the 30-year company anniversary of the IT service provider headquartered in Grafenrheinfeld.

FIS Informationssysteme und Consulting GmbH recently took an excellent second place in the "Hack2Build" SAP competition. The focus was on the development of a prototype for a use case in the supplier self-service based on SAP Integration Suite and the SAP Business Technology Platform (SAP BTP).

Trade and e-commerce are the DNA of the FIS Group: 30 years ago, Gert Lang, the founder of FIS, set himself the goal of optimizing SAP applications for technical wholesale. The development of a tailored e-commerce platform for the wholesale sector began as early as 2002. The e-commerce competence of FIS is completed by the expertise of Medienwerft - the agency for e-commerce and brands.

Grafenrheinfeld — FIS Informationssysteme und Consulting GmbH today announced that the successful use of its FIS/TradeFlex application by its customer Re-In Retail International GmbH received first place in the SAP Business Technology Platform Customer Success Contest 2021 for SAP partners in the MEE region.

Climate change is the key task of our time. The consequences of global warming are becoming more and more apparent and the pressure on policy makers and companies is growing. There is now a global consensus that man-made climate change must urgently be addressed.

The doors of Vogel Convention Center in Würzburg open and people with beaming and expectant faces enter the event location. On the occasion of FISinsITe 2022 (taking place on May 11 and 12), one could feel how happy FIS customers, partners and employees were to finally meet personally after the long period of pandemic.

Omnichannel, personalization and automation: in modern marketing, an innovative software solution is the basis for successful and up-to-date communication with prospective customers and existing customers. Data and processes need to be controlled in one central application if marketers wish to know the customers and their requirements and make this knowledge the focus of their marketing activities.

From now on, the SAP Signavio Process Transformation Suite is part of the FIS portfolio. The platform helps companies better understand, transform and control their own business processes. A consistent process organization is built by combining process and experience data, which increases efficiency.

FIS Informationssysteme und Consulting GmbH supports the "Relief Action for Children in the Ukraine" of the Bundesverband Deutsche Kindertafel e.V. (Federal Association of German Food Charity for Children) and has called on its staff to make donations in kind. The helpfulness is great and 40 cardboard boxes with donations in kind were collected during the last few days.

FIS Informationssysteme und Consulting GmbH (FIS) has sold its FIS-SST Sp. z o. o. (FIS-SST) subsidiary, the software company with excellent development expertise in Java, Microsoft and ABAP technologies, to Q_PERIOR AG (Q_PERIOR).

Successful go-live on the ManoMano online marketplace: at Re-In Retail International GmbH, the interfaces used to date to connect the ManoMano online marketplace were successfully replaced by the FIS/TradeFlex application. The productive migration was implemented to the complete satisfaction of the customer.

On January 07, 2022, FIS welcomed four new students starting their first practice phase of their dual study program at the company’s headquarters in Grafenrheinfeld.

Last weekend, as you will probably already have learned from the press, the BSI (Bundesamt für Sicherheit in der Informationstechnik - German Federal Office for Information Security) released a security announcement on "log4j". In the meantime, this announcement has reached the highest alert level.

Traditionally, FIS has been dispensing with giving Christmas gifts to customers for many years and will instead donate 10,000 euros to “Doctors Without Borders e.V.” (registered asssociation) and 5,000 euros to regional association “Schweinfurter Kindertafel e.V.” (Schweinfurt food charity for children, registered association) this year.

In October, FIS was certified as an SAP Partner Center of Expertise (PCoE) for the second time in a row via Compact Audit.

This year, there was a lot going on at FIS: the groundbreaking ceremony for another office building, significant investments in the FIS solutions and exciting customer projects. Now, the reorganization of the FIS management board will follow in the new year. Dieter Ball and Dirk Schneider will take on the role as new managing directors in November 2021, replacing Wolfgang Ebner and Frank Schöngarth as long-serving managing directors.

Digital Commerce Award for e-Shop with Customer Collection: The Swiss online shop of Meier Tobler AG ranked third in the "Omnichannel and innovation" category of the coveted Digital Commerce Award.

The FIS/edc Next Generation 2021 solution for automated document processes and FIS/xee Business- and Process Integration 2021 have again achieved SAP certified integration with SAP S/4HANA®. With the latest certification for FIS/edc Next Generation 2021, SAP also certifies the compatibility with SAP S/4HANA Cloud, private edition.

SAP consistently relies on quarterly upgrades of its SAP CX applications in the cloud. With the current SAP Sales Cloud release (upgrade of the productive systems on August 21, 2021), however, not only the announced new functionalities were made available. The licensing model for SAP Sales Cloud and SAP Service Cloud will also change: in the future, SAP will differentiate between SAP Sales and Service Core as well as various optimizations.

FIS Informationssysteme und Consulting GmbH (FIS) celebrates topping-out ceremony of its new company building.

The FIS Medienwerft subsidiary has obtained the SAP "Gold" status, which represents the highest status in the PartnerEdge program for channel partners. This status honors the outstanding SAP expertise of Medienwerft.

By integrating with SAP S/4HANA®, the solution from FIS Informationssysteme und Consulting GmbH makes selling via online marketplaces easy by integrating with the sellers’ SAP landscapes and implementing automated end-to-end processes.

On September 01, 2021, FIS welcomed five new trainees starting their vocational training as IT specialists for application development (m/f/d) at the company’s headquarters in Grafenrheinfeld.

The implementation of the new Warehouse Management system has been a full success: Now, FRÄNKISCHE organizes its complex warehouse logistics with SAP Extended Warehouse Management, thereby creating the basis for further process digitizations.

As a thank you for the COVID-19 vaccinations carried out for FIS employees by physician Dr. van Gelder from the Mainbogenpraxis, FIS donates 2,000 euros in his name to Elterninitiative leukämie- und tumorkranker Kinder Würzburg e.V. (Parents' Initiative for Children with Leukemia and Tumors).

FIS Informationssysteme und Consulting GmbH (FIS), together with its subsidiary FIS-ASP Application Service Providing und IT-Outsourcing GmbH (FIS-ASP), donates comforter teddy bears worth €500 to the Bavarian Red Cross (BRK), the St. Josef Hospital and the Leopoldina Hospital.

FIS Informationssysteme und Consulting GmbH from Grafenrheinfeld is awarded as NEW WORK Employer 2021.

On Friday, May 7, 2021, the first employees at FIS were vaccinated against the coronavirus in cooperation with Mainbogenpraxis Sennfeld.

Cooperation between Industry and University Paves the Way to a Successful Career Start at FIS

Following the success of the last two years, FIS Informationssysteme und Consulting GmbH (FIS) is again implementing a trainee program this year. The program prepares graduates for the demanding tasks in SAP consulting.

FIS Informationssysteme und Consulting GmbH (FIS) erects new company building at its Grafenrheinfeld headquarters

SAP recently introduced the new "RISE with SAP" offer to help companies make the transition to the SAP S/4HANA cloud. Major advantage: customers benefit from faster payback. In the future, FIS will strategically build on this and advise you on the way to cloud ERP.

With the transformation of SAP Cloud Platform to SAP Business Technology Platform, SAP continues to focus on the holistic digitization approach.

In a fundraising campaign among the FIS employees, € 12,550 were collected for UNICEF.

FIS Informationssysteme und Consulting GmbH (FIS) attaches great importance to the promotion of young talent and training within its own company. In order to find the right skilled labor of tomorrow, FIS participates in Girls' Day, an event supported by the Federal Ministry of Education and Research, and organizes two practical training weeks of its own.

It is a challenge for companies to assess the sales development. Standard retailing systems are not able to calculate possible deviations from forecasts. FIS would like to change this by using artificial intelligence (AI) for the OBER project (optimum inventory planning for resource conservation).

FIS zahlt inFIS thanks its employees for their great commitment in 2020 by paying all staff members a Corona bonus amounting to a total of € 615,000.

FIS Informationssysteme und Consulting GmbH (FIS) does without Christmas presents for customers and partners and instead donates 15,000 Euros to UNICEF.

The FIS Group extends its e-commerce know-how by expertise in headless commerce.

Train IT-supported planning in industry already during your studies: In the new FIS-SAP Laboratory at Campus Ledward in Schweinfurt, students of the University of Applied Sciences Würzburg-Schweinfurt (FHWS) can gain valuable experience for their professional future.

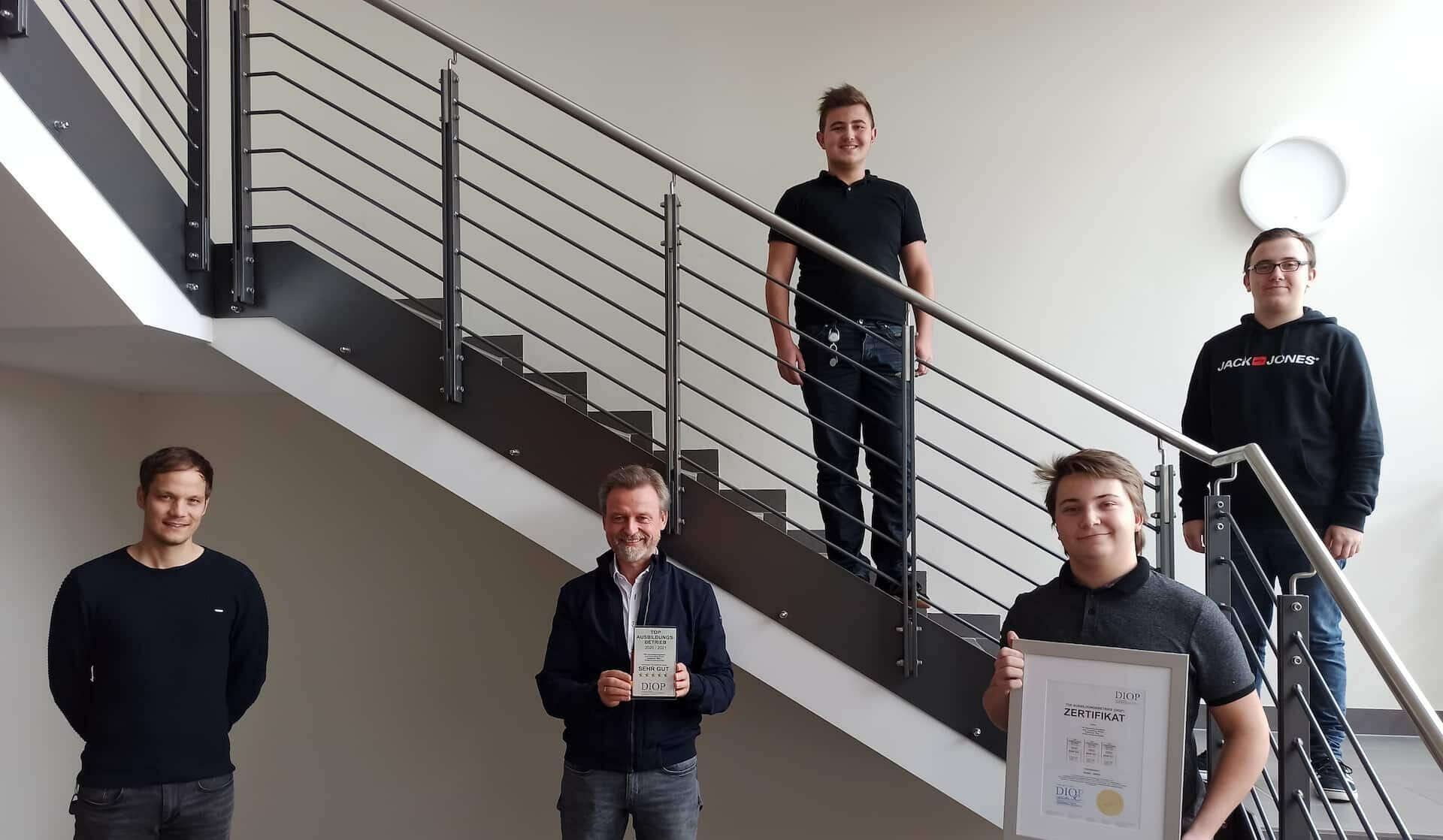

FIS has been awarded with the highest score (“very good”) by the Deutsches Institut für Qualitätsstandards und -prüfung e.V. (German Institute for Quality Standards and Inspection) for its excellent vocational training program.

FIS is honored as a company active in further training due to outstanding further training measures.

FIS wins the Best Workplace Award in the "Large Companies" category and is therefore honored for the design of a particularly attractive workplace concept.

At this year's health day, FIS takes up the hygiene issue, which is highly topical due to Corona. With a newly developed safety concept and in cooperation with the BARMER health insurance company, another successful health day takes place.

On September 1, 2020, new trainees will start their vocational training at FIS.

SAP Gold Partner FIS validated again as expert for the SAP Warehouse Management solution

Extending the range of coverage, optimizing sales opportunities, increasing efficiency: Re-In Retail International GmbH has long achieved these objectives successfully by integrating online marketplaces for instance.

On July 14, 2020, interested pupils had the chance to inform themselves about a dual study program at the “FIS Taster Afternoon”.

The newly designed FIS pupil webinar on website programming offered pupils an exciting alternative for spending their Whitsun holidays.

The online shop developed by the FIS Group for Bartscher GmbH – one of the largest B2B providers in the commercial kitchen sector – has been enhanced by Bartscher Warehouse.

In the future, SAP Marketing Cloud will form the central platform for lean and automated marketing processes and enhance the online store of the roofing materials trader.

The SAP Consultant trainee program has entered the next round. However, some obstacles must be overcome this year due to the Corona restrictions.

Together with the Technical University of Munich, the Fraunhofer Institute for Integrated Circuits IIS and eight other project partners, FIS is working on the implementation of a picking system with RFID tags. FIS, an SAP partner with "Gold" status, is provider of ideas and initiator for the project.

In the future, SAP Marketing Cloud will form the central platform for lean and automated marketing processes and enhance the online store of the roofing materials trader.

SAP is creating a discussion platform at SAP NOW to exchange views on trade challenges and solutions for the best possible customer experience.

FIS received the award as TOP National Employer from the renowned business magazine Focus-Business.

Two strong partners for HR management in SAP

With FIS/TradeFlex, the enterprise integrates online marketplaces into its SAP system; at the beginning, Fnac in France was connected.

FIS donates 15,000 Euros to the Elterninitiative leukämie- und tumorkranker Kinder Würzburg e.V. (Parents' Initiative for Children with Leukemia and Tumor-related Illnesses)

The recertification of FIS as a Partner Center of Expertise (PCoE) was awarded for the first time without auditing. For the long-standing SAP partner with "Gold" status, this is an extraordinary recognition of its support services.

For the third time, the ‘Capital’ business magazine publishes a study on the best training companies / FIS is one of them

FIS integrates the cloud-based CRM solution into the ERP system and other existing systems of leading vehicle manufacturer Kässbohrer.

The sought-after information event for HR departments focusing on SAP HCM takes place in Schweinfurt on December 19.

On November 05, 2019, the 2019 SAP “Warehouse and Transport Management” Information Day takes place in Wiesbaden under the motto “Freedom for innovation via networked logistics”. FIS, an SAP partner with ‘Gold’ status and one-stop provider, is represented at the meeting place of the industry community and shows why FIS is the right partner for warehouse management from the planning and implementation of the software solution to the provision of hardware.

Holistic perspective and particular strengths in integrating the warehouse solution in SAP ERP

As of late, the online presence of Dachdecker-Einkauf Süd eG (DE Süd) does not only offer an overview of the market-leading trader’s roof products to B2B customers, but has now also been complemented by a Web shop.

FIS as one of the leading SAP service providers in Germany has received the "Bayerns Best 50" award. With this award, FIS, a Franconian company, is being honored as one of the 50 medium-sized companies with above-average success in Bavaria.

Operate all steps of the sales process in a single solution in the SAP standard system – connection of Ebay, Amazon, Mercateo and many more.

In Nuremberg, FIS, an SAP partner with "Gold" status, shows how companies can consistently focus on the needs of their customers in times of digitization and inspire them with digital solutions.

The positive entrepreneurship of FIS, an SAP partner with "Gold" status, sets the standard for the Bavarian economy as a whole.

Cloud-based CRM as ideal solution: quickly implemented, the Sales Cloud solution offers everything SMEs need for their customer management.

Integrated Web shop, the connection of online marketplaces and optimized logistics processes - intelligent companies enthuse their customers

A total of nine candidates were officially given the starting signal for their six-month training as SAP consultants.

Sonepar gets ready for the future: At the electrical wholesaler, FIS carried out one of the largest S/4HANA transitions in Germany ever in terms of document volume.

Starting signal for a modern future: Printing machine manufacturer replicates more than 1,000 data records from its SAP system to SAP SuccessFactors.

FIS Informationssysteme und Consulting GmbH (FIS) headquartered in Grafenrheinfeld remains true to its philosophy of supporting disadvantaged and vulnerable children

EDI conversion and communication with the process integration tool of the SAP partner with "Gold" status.

New automated warehouse near Milan in just nine months – FIS combines SAP Extended Warehouse Management with existing ERP solution

The EcoVadis Silver Medal certifies that the SAP "Gold" partner's compliance with global CSR standards is well above the industry average.

The hosting specialist provides certified solutions from SAP PMC at predictable, monthly costs.

The subsidiary of the Schwäbisch Hall building society moves CRM into SAP Sales Cloud and integrates it with further SAP modules.

How to become a #improver in six months – certified SAP specialist with an SAP partner with "Gold" status

The sought-after information event for HR departments using SAP HCM takes place in Schweinfurt on December 18, 2018.

The FIS management board is remaining true to its investments in the economic region of Lower Franconia by enlarging the existing FIS Campus with a third office building.

On time for the start of the new class of trainees, the FIS/Berichtsheft application used in the current 2.0 Release has again achieved the SAP certification.

The New Business Lab of the FIS team provides a real innovative advantage.

SAP is further expanding its marketing, sales and service activities.

The latest SAP certificate attests that the new FIS/edc product generation named "FIS/edc NextGeneration" has been integrated successfully into SAP S/4HANA. It also certifies the FIS/edc integration into SAP NetWeaver.

FIS sets the course for successful business integration with the new SAP product generation.

On the occasion of this year’s FIS Innovation Day, FIS impressively proved how agile and digital challenges can be faced in a constructive way.

The SAP partner with "Gold" status keeps pace with SAP’s product development and continues to fulfill all SAP service and support standards.

During the 2018 LogiMAT/TradeWorld show, FIS and FIS-iLog presented services and products for SAP warehouse management and collaboration in the logistics sector.

FIS, its customers and experts from science and economy make digital transformation tangible.

SAP users give FIS top ratings in all surveyed categories of SAP software maintenance.

SAP SE has named the FIS/Berichtsheft app as one of the top apps in the 2017 MEE (Middle/East Europe) SAP Cloud Platform App Contest.

FIS donates to the emergency fund of Plan International Deutschland.

FIS has put a new SAP ERP system in connection with FIS/wws at all groups of the leading provider for sanitary, heating and air condition technology into productive use.

FIS supports traditional North German technical wholesale company in managing the changeover to SAP and the FIS wholesale solution.

FIS has implemented a new SAP system at SPECK Pumpen Verkaufsgesellschaft GmbH based in Neunkirchen am Sand. The internationally operating manufacturer now considers itself well equipped for further expansion.

IHK Würzburg-Schweinfurt presented a certificate of the 25th company anniversary to the FIS management board honoring the outstanding entrepreneurial performance of FIS.

In the SAP HANA Vendor Benchmark, the one-stop provider for medium-sized businesses is leader in four important categories.

At CeBIT 2017, FIS also registered a great deal of interest in S/4HANA-based retailing and SAP Hybris solutions.

FIS GmbH masters the latest data exchange standards. FIS customers are optimally equipped with OFTP2 for the future communication with business partners.

After a 19-week construction phase, FIS Informationssysteme und Consulting GmbH (FIS) celebrated the topping-out ceremony for its new company building.

High efficiency and an innovative corporate culture are the crucial keys for any company wishing to succeed in heavy competition. The brains of meanwhile over 600 employees are full of ideas for making the company even more efficient and innovative.

The interest in the FIS expert forums remains unbroken. The latest event taking place in Cologne on October 6, 2016 was once again fully booked with more than 50 participants.

The SAP Integration and Certification Center has successfully certified FIS/mpm for the integration with SAP Netweaver® via the "ABAP Add-On Deployment for SAP Enterprise Resource Planning" SAP integration scenario.